Strength. Reliability. Flexibility.

Planetary Gearbox Manufacturere

how planetary gearbox works

A planetary gearbox, also known as an epicyclic gearbox, is a type of gear system that consists of multiple gears arranged in a specific configuration. It is called “planetary” because the gears rotate around a central sun gear, similar to the motion of planets revolving around the sun.

Sun Gear

The sun gear is a centrally located gear that remains stationary. It is typically in the center of the gear system and receives the input power.

Planet Gears

These gears are smaller in size and surround the sun gear. They are connected to an outer ring gear called the annulus.

Annulus

The annulus is a large outer ring gear that meshes with the planet gears. It is fixed in place and does not rotate during normal operation.

The operation of a planetary gearbox depends on the arrangement of these components. There are different types of planetary gear configurations, but one common arrangement is known as the “simple planetary” or “epicyclic” configuration.

In the simple planetary configuration, the sun gear is driven by the input shaft, which provides the input power. As the sun gear rotates, it drives the planet gears, which are meshed with both the sun gear and the annulus. The planet gears rotate on their own axes and also orbit around the sun gear.

The rotation of the planet gears causes the annulus to rotate in the opposite direction. The annulus is held stationary by external means, such as being fixed to the gearbox casing. This relative motion between the sun gear, planet gears, and annulus creates a gear reduction or gear multiplication effect, depending on the specific configuration and gear ratios.

Features of Planetary Gearbox

A planetary gearbox is a type of gearbox that is commonly used in various industrial applications. It consists of sun gear, planet gear, and ring gear. One of the key features of a planetary gearbox is its compact size, which allows it to transmit high torque in a relatively small package. This makes it ideal for use in applications where space is limited. Another important feature of a planetary gearbox is its ability to provide a wide range of gear ratios, which allows it to be used in a variety of applications with different speed and torque requirements. Additionally, planetary gearboxes are known for their high efficiency, which is due to their ability to distribute the load among multiple planet gears, resulting in lower wear and tear. They are also known for their noiseless operation, which makes them ideal for use in applications where noise is a concern. Finally, they are highly durable and require minimal maintenance, making them a popular choice in many industries, including automotive, aerospace, and robotics.

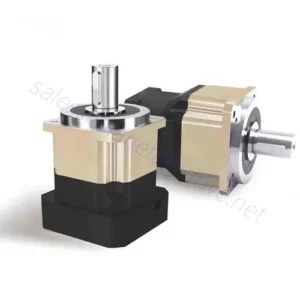

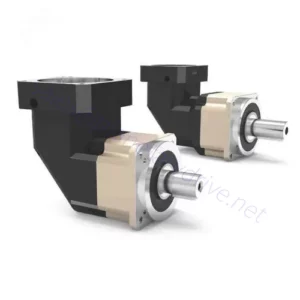

Planetary Gearbox for Sale

As a planetary gearbox manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Planetary Gearbox Application

Planetary gearboxes are widely used in various industries due to their compact design, high torque capacity, and high power-to-weight ratio. Some common applications of planetary gearboxes include:

Automotive industry

Planetary gearboxes are frequently used in automatic transmissions, where they provide smooth gear shifting and efficient torque distribution. They are also used in hybrid and electric vehicle drivetrains to convert the high rotational speed of electric motors to a suitable speed for vehicle wheels.

Aerospace

Planetary gearboxes are utilized in the aerospace industry, where they contribute to the reduction of weight and size in aircraft engines and helicopter rotors. They provide accurate speed and torque control for critical systems, such as landing gear and flap actuation.

Industrial automation

In robotics and automated systems, planetary gearboxes are used to provide precise motion control and high torque capabilities. They are often paired with servo motors and stepper motors for various positioning, orientation, and pick-and-place tasks.

Wind Turbines

Planetary gearboxes are used in the drivetrain of wind turbines, where they convert the low-speed, high-torque input from the wind rotor into high-speed, low-torque output for the generator. This allows for efficient power generation and reduced wear on the turbine components.

Heavy machinery

In heavy-duty machinery such as construction equipment, mining equipment, and cranes, planetary gearboxes provide the necessary torque and speed control for various tasks, such as lifting, digging, and material handling.

Marine propulsion

Planetary gearboxes are used in marine propulsion systems, where they transfer power from the engine to the propellers. They help in achieving the required speed and torque for efficient vessel movement and maneuverability.

How Do I Know What Planetary Gearbox I Need?

Determining the right planetary gearbox for your specific needs involves considering several factors. First, you should evaluate the desired output speed and torque requirements of your application. This includes understanding the input power, rotational speed, and torque range that the gearbox must handle. Next, consider the gear ratio needed to achieve the desired output speed and torque. This involves analyzing the speed and torque relationship between the input and output shafts and selecting the appropriate gear ratios.

Additionally, take into account the physical dimensions and mounting requirements, as well as any specific environmental conditions, such as temperature, vibration, or load variations, that the gearbox will encounter. Finally, consider factors like efficiency, backlash, noise levels, and maintenance requirements to ensure the gearbox meets your performance and reliability expectations. Consulting with our specialists can also provide valuable guidance in selecting the most suitable planetary gearbox for your application.

Precision CNC Manufacturing

We know that the production of gear reducers requires extremely precise machining of each reducer produced within tight tolerances.

We have invested in some of the most advanced processing technologies in Germany and Japan, enabling us to guarantee precision and consistent quality in every product we manufacture.

We perform all gearbox machining operations in-house, from roughing to finishing, gear grinding and hobbing, and all aspects of quality control and assembly.

For decades, we have accumulated rich expertise in the processing and production of reducers, from light reducers to heavy reducers. Our experienced technicians and mechanics are fully trained and regularly receive additional refresher training as new technologies and requirements arise.

Best Planetary Gearbox Support and Service

We understand how important fast and efficient service is to your business. We stock an extensive parts inventory for all gearheads and can provide fast on-site service should your need arise. Our components are also standard sizes and can be sized for replacement with standard parts from other brands including internal components. If you have any questions or needs, please send us an email.